Reduction of Water Vapour Sorption of Clay Plasters through Stabilising Agents

The influence of stabilising agents on the water vapour sorption of earthen building materials was investigated on a trial basis as part of the master's thesis.

Motivation

The air moisture absorption of clay plasters is usually many times higher than that of other plaster mortars. The test procedure and declaration for this property is anchored in the standard for clay plasters DIN 18947. While the stabilisation of earthen building materials with chemically setting binder additives such as cement or gypsum is not permitted in Germany, earthen building materials and also earthen plasters are often stabilised worldwide in order to increase their strength. This type of stabilisation is associated with the loss of replasticisability and thus reusability, but also with the reduction of the water vapour sorption capacity. The standard for clay boards DIN 18948 distinguishes between water-soluble stabilisation, which is similar in nature to clay bonding, and chemical stabilisation. The same applies to clay thin-layer coatings, which are regulated by the DVL Technical Bulletin TM 06. The influence of stabilising agents on the water vapour sorption capacity of earthen building materials has been little investigated so far.

Task

The influence of stabilising agents on the water vapour sorption of earthen building materials was investigated on a trial basis in the context of the master's thesis. Since plasters have a particular influence on the indoor climate, the investigations were carried out on clay plaster mortars. Due to the availability of the moulds and material-specific testing equipment, the tests were carried out in the laboratory rooms of ZRS Ingenieure GmbH. The influence of the following stabilising agents on a clay plaster of water vapour sorption class WS III was investigated:

- Methyl cellulose (CM)

- Starch (FP)

- Cement (CE)

- Hydraulic lime (NH)

- Non-hydraulic lime (WK)

- Gypsum (CA)

- Polymer dispersion (MC).

Corresponding formulations were determined by means of theoretical preliminary considerations and experimentally supported investigations. In the theoretical consideration, the state of knowledge on this subject has been analysed. The effect of the stabilising agents on the material or mineral structure was considered theoretically.

Results

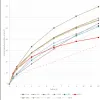

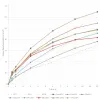

The results show that the use of stabilising agents has a reducing effect on the water vapour adsorption capacity of clay plasters to varying degrees. Cement-modified plasters, for example, showed a 22 % reduction in sorption capacity, whereas the lime-modified test specimens showed a reduction of around 18 %. As a stabilising agent, gypsum caused a reduction of 15 %, whereas starch and methyl cellulose caused a reduction in sorption capacity of around 25 %. The greatest reduction in water vapour adsorption capacity was caused by modification with epoxy resin. This had an influence of about 40 %.

In order to determine the superposition effects of both the carbonation of the hydrated lime (in the case of lime & cement) and the hydration effects during post-curing of the cement, the individual mixtures were first subjected to storage in a humid climate at (23 ± 2) °C / (80 ± 5) % RLF after the actual water vapour adsorption moisture test and then to storage in a standard climate at (23 ± 2) °C / (50 ± 5) % RLF until the mass constants were reached. The results after the humid climate storage were significant, especially for the lime and cement-modified mortars. The differences in the water vapour adsorption properties compared to those of the pure clay plaster were around 25 % for the lime-modified mortars and around 41 % for the cement-modified mortars. This confirmed the assumption that previously unexamined phenomena in the chemical reactions have a reducing effect. Finally, it should be noted that chemical stabilisation not only limits one of the main properties of earthen building materials, but in the case of polymer dispersions, even eliminates it altogether: its recycling properties and replasticisability.

Other participants

Project management

Project management

Prof. Dr.-Ing. Christof Ziegert

Honorary Professor in the Department of Civil Engineering

Master's graduate

Dipl.-Ing. (FH) Peter Schlacht